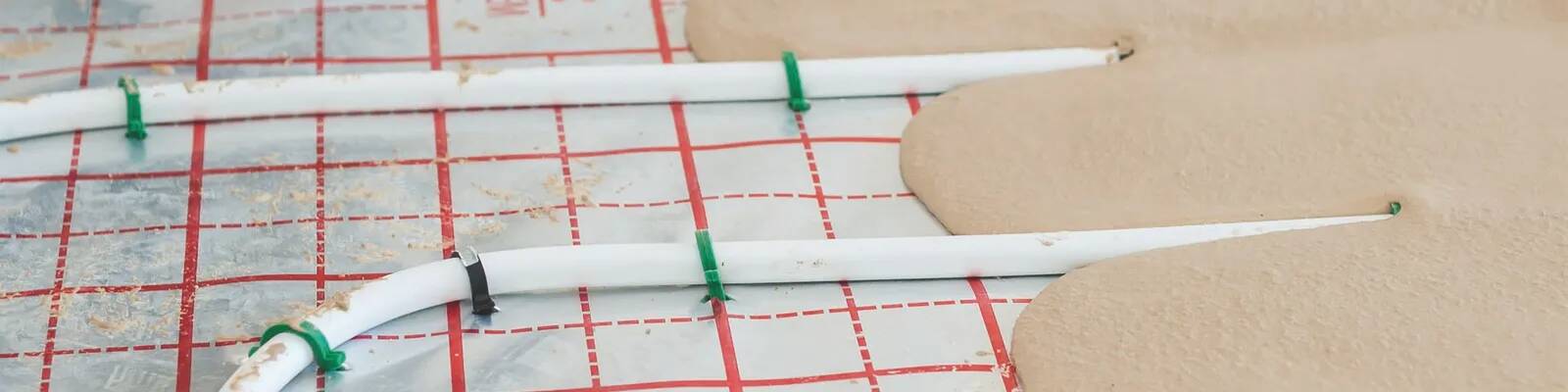

Used to lay thin-layer (2-20 mm) cement ground coats, manually or mechanically, in order to level surfaces under parquets, carpeting, ceramic tile floors etc. inside buildings. The product is classified as cement screed, CT-C30-F7 type. It can be applied on concrete layers, as well as on concrete finishes with floor heating.

Packaged in 25kg containers.

Preparation of mortar: Empty the package (25kg) into ca. 5.5-5.75 l of clean water. Stir the mixture with a low-evolution agitator, until a smooth mass is obtained. Wait fro 2 minutes and stir again. The use of at least 2 containers is recommended, as this considerably facilitates fast and even pouring and joining of the cast screed fields. The mortar can also be mixed and fed with a mixing and pumping unit, with a design guaranteeing precise mixing and feeding of water. Attention should be paid so that water is not added in excess, as this may worsen the strength and increase mortar shrinking.

Mortar casting: The mass should be cast in parallel belts. Mortar portions should be cast in such a manner that the already cast fields could be connected when they are still liquid, which guarantees a smooth surface. The mortar can also be evenly distributed with a steel trowel or trapezoidal floating rule, at a desired thickness. Surfaces cast in this manner should be de-aerated with a spiked roller. Mortar should be laid non-stop, until the entire surface is covered.

The temperature of the base and its surroundings during the screed application and drying should be between +5°C and 25°C. The optimal application temperature is 20°C. The cast screed should be protected against drying too fast (exposure to increased temperatures, draughts). All expansion joints in the base should be repeated in the layer of cast screed. The maximum surface of the expansion field may not exceed 25 square meters. Ceramic cladding can be applied only after the lapse of a 24-hour period. With other cladding types (PVC, parquet, panels), base moisture measurements should be carried out, whose results should be compliant with recommendations of the manufacturers of the aforementioned cladding. Surfaces exposed to contamination with screed should be secured; any stains should be removed before drying. Tools should be washed with water directly after the completion of works.

Information contained in the manual help ensure the optimal use of the product, however, it does not create any legal liability of the Manufacturer, due to the fact that the conditions of use remain outside of its control. We do not accept any responsibility if the material is combined with products from other Manufacturers. On the surface of set screed, differences in shade and appearance may occur, depending on the production batch, methods of screed care during setting, and the casting method.